Aeration Locations

The aeration phase removes organic matter, fine particles, and potentially toxic and harmful chemicals from the influent that enters the system. Read on to learn more about wastewater treatment aeration locations.

Aeration Basins & Aerobic Digesters

An aerated lagoon or aerated basin is a holding treatment pond that supplies artificial aeration. Artificial aeration promotes the biological oxidation of wastewater.

Aeration basins are large, open earthen lagoons or ponds. The large surface areas involved cause more drastic temperature variations than those found in aerobic digesters. Thus, causing variations in sludge retention times. If solids return to the aeration basin process, then there is no difference between an aeration basin and the activated sludge process.

Aerobic digesters are tanks constructed of concrete and are rectangular. This is so multiple tanks can share common walls. Large tanks would have fewer diffusers where most plants have at least two digesters. The aerobic digestion process can be continuous or batch.

Suspension Mixed Lagoons

The objective of suspension mixed lagoons is to convert the soluble, biodegradable organics in the influent into biomass that can settle as sludge. Usually, the effluent is then put in a second pond where the sludge can settle. The effluent is then removed from the top with a low chemical oxygen demand (COD), while the sludge accumulates on the floor and undergoes anaerobic stabilization.

Suspension Mixed Lagoons

Suspension mixed lagoons convert the soluble, biodegradable organics in the influent into biomass that can settle as sludge. The effluent goes to a second pond where the sludge can settle. Then, it is removed from the top with a low chemical oxygen demand (COD), while the sludge accumulates on the floor and undergoes anaerobic stabilization.

Floating Surface Aerators

Two functions are provided in a surface aerated system:

(1) Transfer air into the basins to facilitate biological oxidation reactions.

(2) They provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater, and microbes).

The floating surface aerators deliver oxygen for aeration. However, surface aerators do not provide mixing that is equivalent to what is achieved in activated sludge systems.

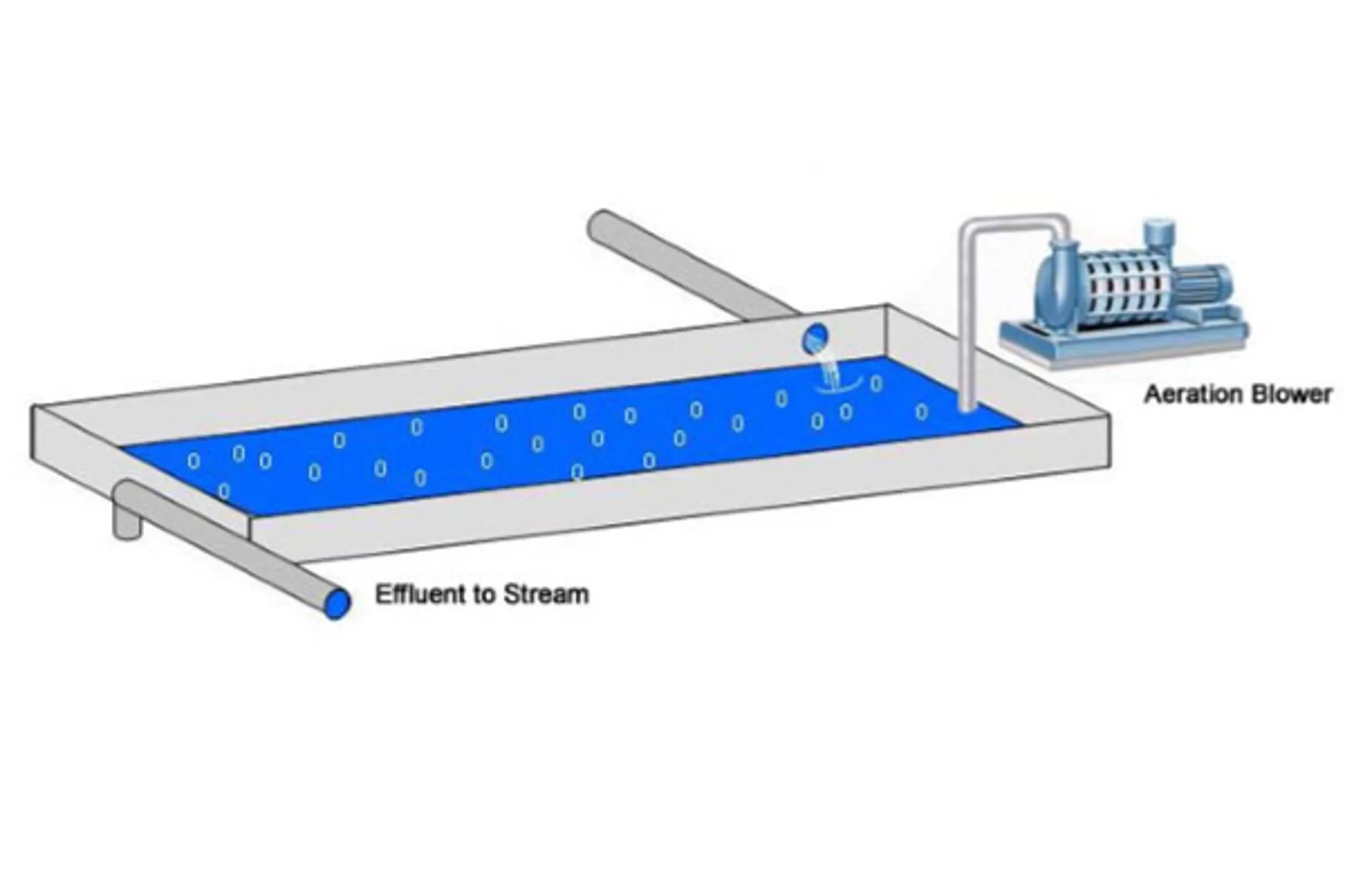

Submerged Diffused Aeration

Submerged diffused air is a form of a diffuser grid inside a lagoon. The two main types of submerged diffused aeration systems for lagoon applications are floating and submerged lateral. Both systems utilize fine or medium bubble diffusers to provide aeration and mixing of the process water. The diffusers can be suspended slightly above the lagoon floor or may rest on the bottom.

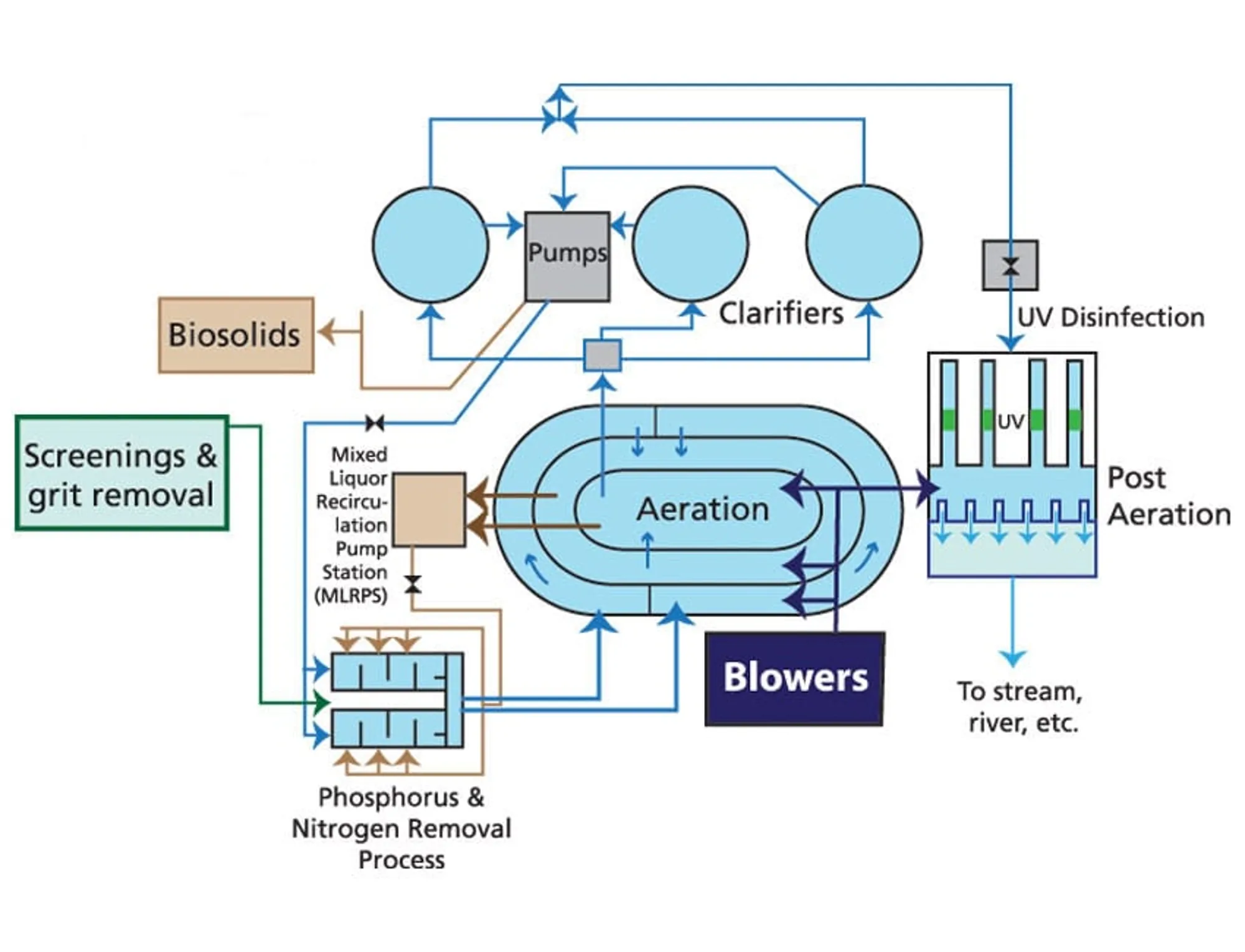

Channel Aeration

Channels that distribute wastewater to the primary sedimentation tanks are aerated to keep the solids in suspension, and independent of the water flow rate. The amount of air required ranges and mixed liquor turns to activated sludge settling tanks that are aerated.

Post Aeration

Requirements for effluent demand high dissolved oxygen levels. The regulation intends to ensure that low dissolved oxygen level effluent does not mix with a receiving stream.

Submerged Diffused Aeration

Submerged diffused air is essentially a form of a diffuser grid inside a lagoon. The two main types of submerged diffused aeration systems for lagoon applications are floating lateral and submerged lateral. Both of these systems utilize fine or medium bubble diffusers to provide aeration and mixing of the process water. The diffusers can be suspended slightly above the lagoon floor or may rest on the bottom.

Channel Aeration

In large wastewater plants, channels that distribute wastewater to the primary sedimentation tanks are aerated to keep the solids in suspension, and independent of the water flow rate. The amount of air required ranges from 2-5 cfm per linear foot of channel (0.2-0.5 m3/linear meter/minute). Frequently, the mixed liquor to activated sludge settling tanks are aerated.

Post Aeration

Recent requirements for effluent demand high dissolved oxygen levels (4 to 8 MG/L). The intent of the regulation is to ensure that low dissolved oxygen level effluent is not mixed with a receiving stream.

One method is cascade aeration, where the effluent is aerated by the turbulence of a series of waterfalls. However, the temperature of the water greatly affects the water’s ability to absorb oxygen.